Step 1: Acquire pallets, join together vertically. Tread fine line between wastefully overusing your ridiculously rare and expensive nails and screws, and under-using them and having the shed fall on your head.

Step 2: Flip pallet-chimeras over and join together horizontally on the other side. Make two sides, with a total of six pallets per side.

Step 3: Stand the two pallet-sides up (with temporary disassembled-shipping-crate supports) and add cross beams to hold them together.

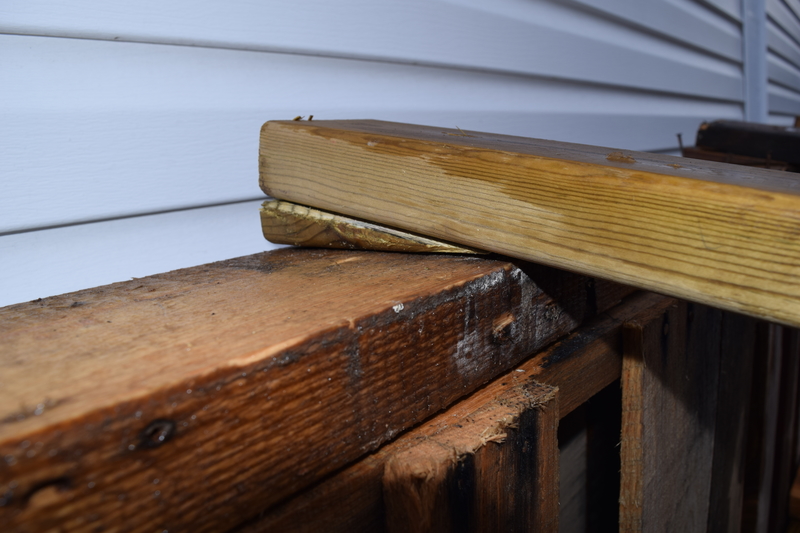

Step 4: Add diagonals sloping down from top of higher side. If ground is uneven and wood is irregular, distorted and scavenged from small isolated town, this will involve lots cutting, shaping and padding.

Step 4b: You can use trigonometry to figure out the slope of your diagonal and cut your beams so they lie flat on the horizontal cross beams. However…

Step 4c: It will take the geometric brilliance of your wife to notice that the off-cut you just made will be the exact right angle for bracing the other end of your diagonal beams too! (I was going to try to somehow cut an 11 degree inset into the top horizontal beam instead! Buh! Totally unnecessarily).

Step 5: Add plywood roof and park your snowmobile.

Bonus tip: If you are not brave enough to risk walking on your new roof, you can instead attach the plywood by leaning out your bedroom window!

Acknowledgments

This production wouldn’t have been possible without the following generous sponsors:

- Faye’s mum and step-dad, who (having read my previous complaint on this blog) sent a shed-saving supply of screws along with Faye’s birthday gift.

- My neighbor, who loaned me his ladder and helped me scavenge wood at the dump.

- My other neighbors, who helped moved the pallet walls into position. Pallets are heavy. Six pallets joined together are insanely heavy and would probably squash you if you dropped them.

- The contractors building a house nearby, who dropped off a whole big load of their scrap wood for me.

- And the number 9. C is for cookie, and that’s good enough for me.

Looking good so far… Flip the table, measure twice, drill pilot holes, attach screws, careful, careful, everything at just the right angle and flip the table back and…

Looking good so far… Flip the table, measure twice, drill pilot holes, attach screws, careful, careful, everything at just the right angle and flip the table back and…