While Tulita may be starved of lumber, it is rich in pallets. I assume they arrive on the barges and ice-road trucks, carrying various goods, and are not worth sending back. People’s yards are full of them, the “board walk” near the local playground is made of them (I’ll grab a picture some day and add it to this post) and the “wood” section of the dump is full of them.

My neighbors just moved into a new, bigger house (they’re having a baby soon) and suddenly found themselves needing a shoe rack. Seemed like a good time to experiment with pallet based construction.

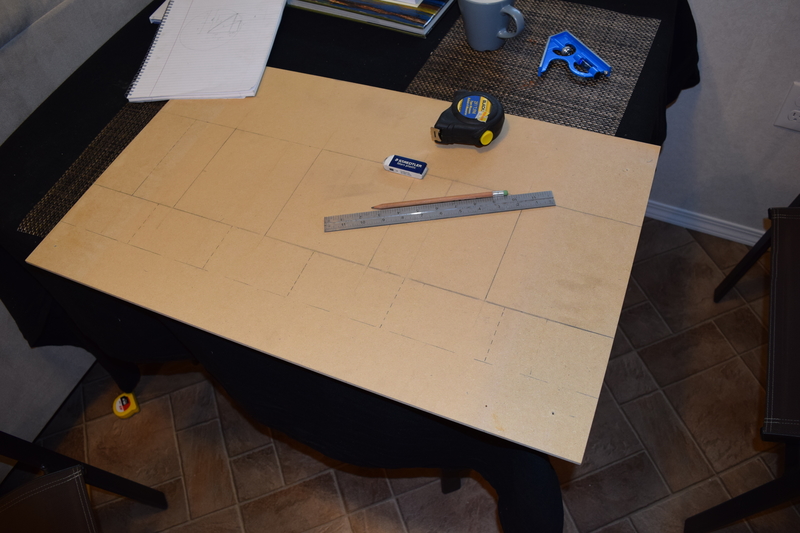

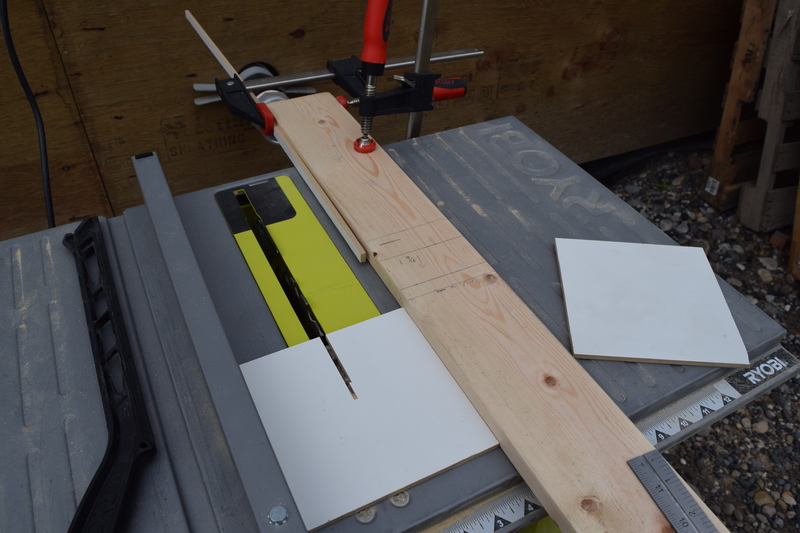

The construction went fine. I just cut a couple of dadoes (like grooves, but across the grain) into the support beams, making them are just big enough to slip the slats into, assembled and presto! One shoe rack!

The tough part, it turns out, is taking the damned pallets apart. Those things are built to stay together! I snapped a hammer in half trying to pry the nails out (lesson learned about cheap hammers…).

I ended up using a reciprocating saw to cut through the nails. Even that was a challenge, because I still needed to bang the slats off enough (despite no room inside to swing a hammer) to fit the saw in between. Found out a few days later that another neighbour owns a massive oversized crowbar that I can borrow! That’s another thing I should have thought to bring up…